EB Machine Process

Electron Beam Machine Process

The EB Machine Process

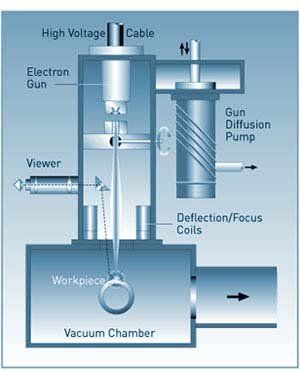

An Electron Beam Welding system is composed of an electron beam gun, a power supply, control system, motion equipment, and vacuum-welding chamber. Fusion of base metals eliminates the need for filler metals (Autogenous welds).

The vacuum requirement for operation of the electron beam equipment eliminates the need for shielding gases and fluxes.

- The electron beam gun has a tungsten filament, which is heated, freeing electrons.

- The electrons are accelerated from the source with high-voltage potential between a cathode and anode.

- The stream of electrons passes through a hole in the anode.

- The beam is directed by magnetic forces of focusing and deflecting coils.

- This beam is directed out of the gun column and strikes the workpiece.

The potential energy of the electrons is transferred to heat upon impact of the workpiece and cuts a perfect hole at the weld joint. Molten metal fills in behind the beam, creating a deep, finished weld. The electron beam stream and workpiece are manipulated by means of precise, computer-driven controls, within a vacuum welding chamber, therefore eliminating oxidation or contamination.

-

About EB Welding

LEARN MORE -

The Value of EB Welding

LEARN MORE -

EB Welding Speed/Strength

LEARN MORE -

EB Machine Process

LEARN MORE

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.